ENFAC KOREA

- ENFAC KOREA

- Business Fields

- Community

- Contact Us

Copyright(C)ENFAC KOREA. All right reserved

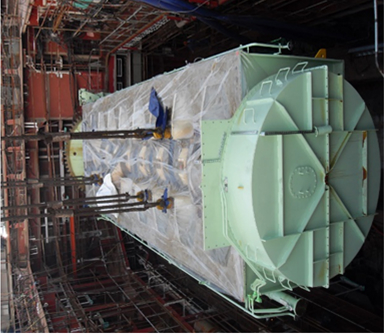

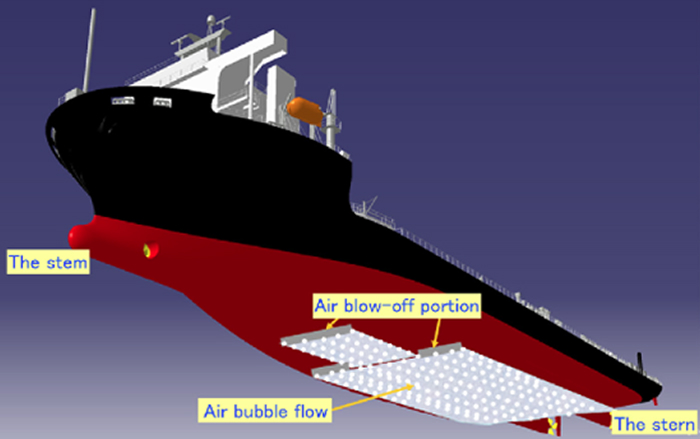

AIR LUBRICATION SYSTEM RETROFIT

Air Lubrication System

Air lubrication system is one of the most efficient way to reduce fuel consumption and associated emissions. It reduces frictional resistance by creating a carpet of microbubbles on the full flat bottom of a vessel’s hull. In keeping up with the emerging necessity of clean ocean, ENFAC KOREA has provided installation service of air lubrication system for new building ships from 2023. We have contracted installation for 36 ships and currently being installed at the shipyard. Air lubrication system can be installed on both new and existing ships with ease. The retrofit procedure is basically same with BWMS & scrubber so that we ensure that we can carry out the retrofit installation for air lubrication system with our knowledge through many years of ship retrofit experience. The capability and proficiency of our workers are impressive and we are proud of the quality of our work. As one of leader company for green ocean, we guarantee you that you will be satisfied our retrofit service for air lubrication system.

COMPRESSOR

Compressor for Air Lubrication System

Compressors are the main equipment that determines the performance and efficiency of Air Lubrication System.

Atlas Copco's non-fueled low-pressure compressor is the only large-capacity (maximum flow rate of 11,500m3/h) compressor used in Air Lubrication System. Built with the latest technology screw element and a closed IP55 motor, it can operate stably even in hot and humid environments, and is very advantageous for energy efficiency by applying inverter technology.

Atlas Copco's low-pressure compressor is optimized for constructing Air Lubrication System and boasts high energy efficiency.

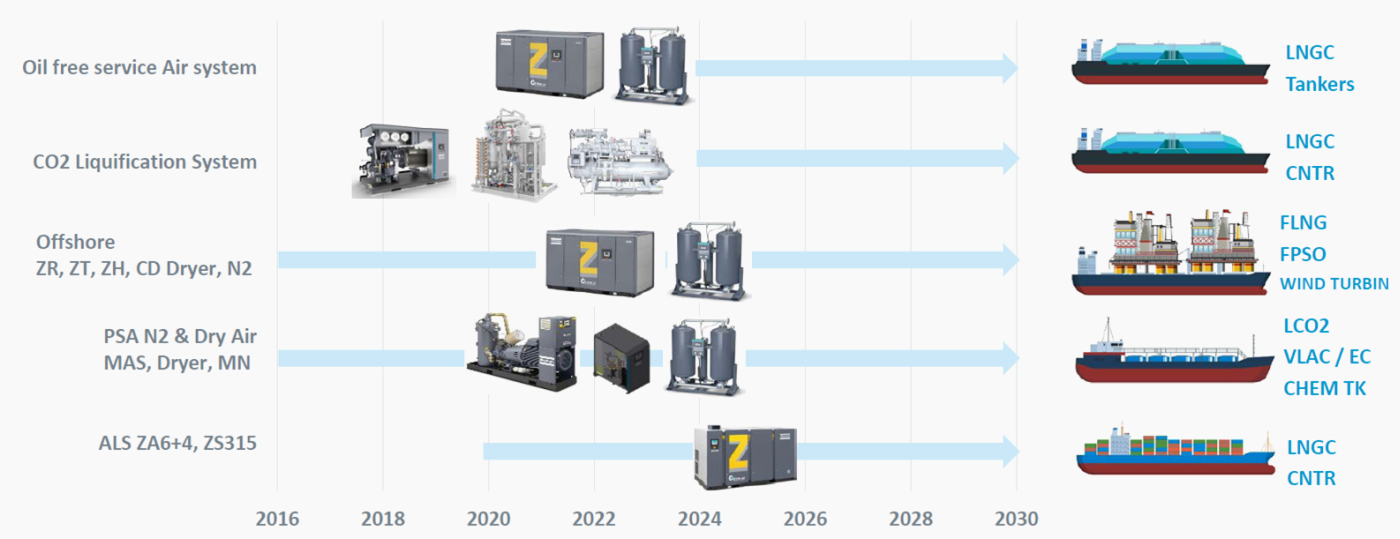

Introduction of Applications

AMP ENGINEERING

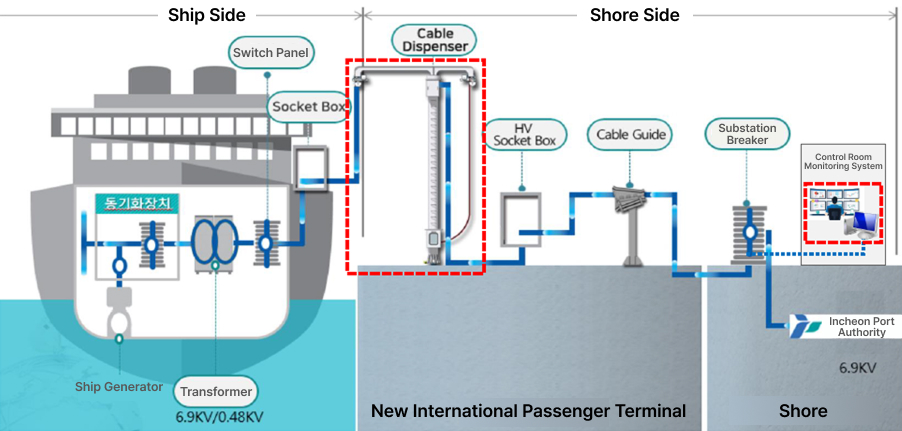

AMP ( Alternative Maritime Power )

Anti-pollution measure which helps in reducing air pollution generated from diesel generators by using shore electric power as a substitute.

AMP provides power for lights, refrigerators, air-conditioners and other equipment on a ship.

Reason to install

The number of deaths from cardiopulmonary diseases caused by fine dust.

Coastal areas are a thousand times more than inland areas and that is the reason why recommended to install AMP. It is one of the best way to reduce emission as alternative technologies for ships during the berthing period.

The Fuel EU Maritime regulation requires that from January 1, 2030, container and passenger ships (including cruise ships) greater than or equal to 5,000 gross tonnage (GT) must connect to shore power in main EU ports in the trans-European transport network.

AMP SYSTEM

AMP set-ups vary depending on the power demand and the type of vessel. In each case, the equipment is unique.

For example, cable management system must be installed onboard for container ships, whereas it must be installed on the shoreside for other types of ships.

Ship diesel generators can be shut down with a resultant reduction in noise, vibrations and emissions, such as particulate matter, nitrogen oxides, sulfur oxides, carbon oxides, and volatile organic compounds. Vessels with power demands higher than 1MVA must establish high-voltage connections (6,6kV or 11kV) with the mainland power grid, implementing suitable equipment according to international regulations and ports requirements.

SCOPE OF WORK

-

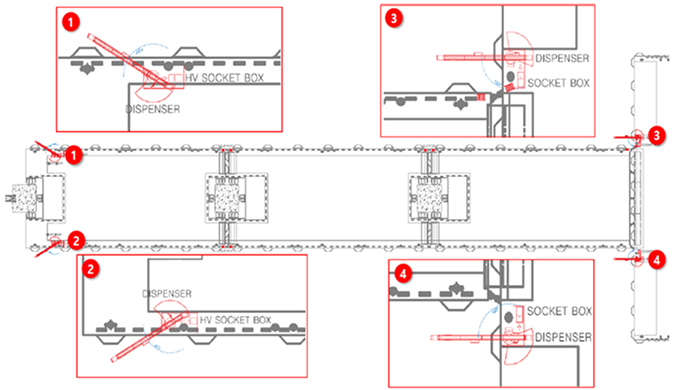

CABLE DISPENSER

1. Remove AMP Dispenser lower concrete slab

2. Install Basement double pad, etc.

-

AMS (ALRAM MONITORING SYSTEM)

1. Communication infrastructure

2. Control system

3. Accessories, etc.

PROCEDURE

Step 01

Analyze on-site status with floor plan

Step 02

Set up an installation schedule to follow through whole period

Step 03

Installation according to the process

1. REMOVAL AND PREPARATION

2. ASSEMBLY AND WELDING

3. INSTALLATION

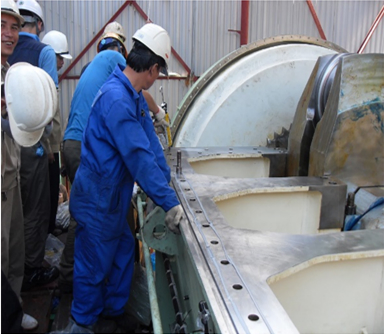

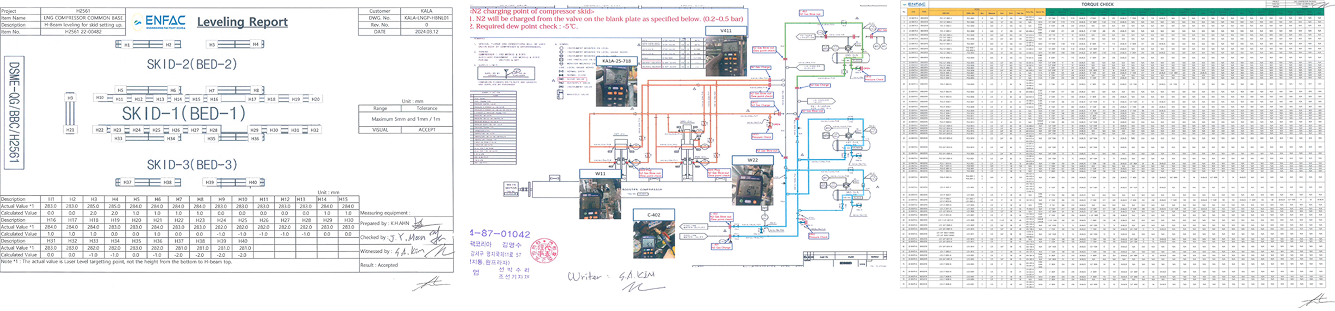

COMPRESSOR SKID INSTALLATION

Compressor Package Unit

The compressor skid is an integral component in the processing, transportation, and storage of hydrocarbons. These skid-mounted units are engineered to compress gases, thereby facilitating their movement through pipelines or into storage vessels.

Work Scope

We provide compressor/equipment assembly, outfitting/ piping installation, all the inspection and test such as final leveling, oil flushing/N2 leak test and etc.

DRAWINGS

We follow all the instructions mentioned at the makers given drawings.

REPORT

There is a designated manager for each project and we try our best to comply all the procedure customer request.

All reports will be submitted as soon as the inspection ends.

HYDROGEN REFUELING STATION DESIGN

DRAWINGS

We basically design the electrical parts according to the station layout what our customer provide.

We provide from 3D scanning to design all the drawings. (Cable installation/Wiring diagram/Cable diagram/Configuration sheet and etc.)

MANUFACTURE & INSTALLATION

We manufacture control panel for pump test skid and install the cable connection.

GENERAL REPAIR

NECESSITY

Marine engine parts need to be checked on regular basis to avoid breakdown or heavy loss caused by ship going off charter. Marine engine repairs are carried out by the marine engineer as per his basic understanding of the machine, sound troubleshooting knowledge and correct techniques used for testing and overhauling.

Marine engineer also have to make sure that all the equipment are working fine without any problem. External agencies such as port state control and flag state will detain the ship if equipment like emergency generator, life boat engine, and fire fighting system are not working properly.

The agencies may fine the ship heavily for these abnormalities.

Engine Overhaul

Start up and disassemble test Replacement of crankshaft

Engine Installation

Engine mounting & technical guidance Engine block replacement

Transmission failed.

-

There is a problem with the server and network.

Please contact us separately. - Close

Your email is being sent.

Please do not close the window and wait a moment.

Your email has been sent.

We will respond as soon as possible.

Thank you for visiting.- Close